When it’s time to re-sheet your flat roof, choosing a material that is both durable and suited to your local weather conditions is essential. As a homeowner, you have several flat roof sheeting options to consider, each with pros and cons in terms of longevity, cost, and installation.

Doing thorough research upfront will help ensure you make the best choice for your needs and budget. Carefully evaluating factors like material composition, warranty, insulation properties, and average lifespan will guide you to the optimal flat roof sheeting material for your property. With the wide variety of products on the market, you owe it to yourself to make an informed decision that will protect your home for years to come.

What Is Flat Roof Sheeting?

Flat roof sheeting refers to the waterproof membrane installed on low-slope or flat roofs to protect the roof deck from weather damage. Several options exist when choosing a flat roof sheeting material, each offering varying levels of durability, insulation, and weather resistance. There are several options to consider when choosing a flat roof sheeting material:

1. Polyvinyl Chloride (PVC)

PVC is a popular synthetic material used for flat roofs due to its durability and chemical resistance. PVC sheeting is flexible and can withstand various weather conditions. However, it can be difficult to install and repair. PVC roofing typically lasts about 20 years.

2. Thermoplastic Polyolefin (TPO)

TPO is a heat-weldable, synthetic material gaining popularity. Its seamless finish is highly reflective, helping to reduce cooling costs. However, as TPO has only been used since the 1990s, its long-term durability remains relatively unknown. On average, TPO roofing lasts 15-20 years.

3. Ethylene Propylene Diene Monomer (EPDM)

EPDM is a durable synthetic rubber material commonly used for flat roofs. It is highly flexible, waterproof, and able to withstand extreme temperatures. With proper installation and maintenance, EPDM roofing can last 20-30 years. However, it requires the use of adhesives, which can release volatile organic compounds (VOCs).

4. Modified Bitumen

This roofing material is composed of asphalt and plastic or rubber polymers. It’s known for being seamless, durable, and resistant to damage. Modified bitumen roofing typically lasts 10-30 years depending on the type. However, installation requires hot asphalt, which can pose hazards.

In summary, the best flat roof sheeting material depends on your needs, priorities, and budget. Discuss the options with a reputable roofing contractor to determine the most suitable for your building and circumstances. Proper installation and maintenance of flat roof sheeting is critical to maximize lifespan.

Pros and Cons of Different Flat Roof Sheeting Materials

When selecting a flat roof sheeting material, you must consider several factors to determine the best option for your needs.

Durability

The durability and lifespan of the material are important considerations. For instance, metal sheeting like galvanised steel or aluminium can last 40-50 years. On the other hand, TPO and PVC membranes have a lifespan of 20-30 years. Asphalt-based roll roofing usually needs replacement after 10-15 years.

Cost

Cost is also significant. Asphalt roll roofing is inexpensive but has a shorter life expectancy. TPO and PVC membranes have moderate upfront costs and longer lifespans, whereas metal sheeting is initially more expensive but lasts longer.

Weather Resistance

The material’s ability to withstand weather directly impacts its performance. Metal sheeting is highly resistant to wind, hail, and rain. TPO and PVC membranes withstand moderate impacts but may puncture. Asphalt-based materials degrade faster in extreme heat or cold.

Ease of Installation

Installation complexity is another factor. Asphalt roll roofing is easy to install, making it ideal for DIY projects, but its lifespan is limited. TPO and PVC membranes require professional installation for the best results. Metal sheeting can be installed by experienced DIYers but requires specialised tools.

In summary, when choosing a flat roof sheeting material, you must evaluate factors like durability, cost, weather resistance, and ease of installation. Selecting the right option for your needs and budget will help ensure maximum protection and performance for your flat roof.

Flat Roof Sheeting Options: Metal vs. Membrane

When selecting a flat roof sheeting material, homeowners typically have two options: metal panels or membrane sheets. Each has its benefits and drawbacks.

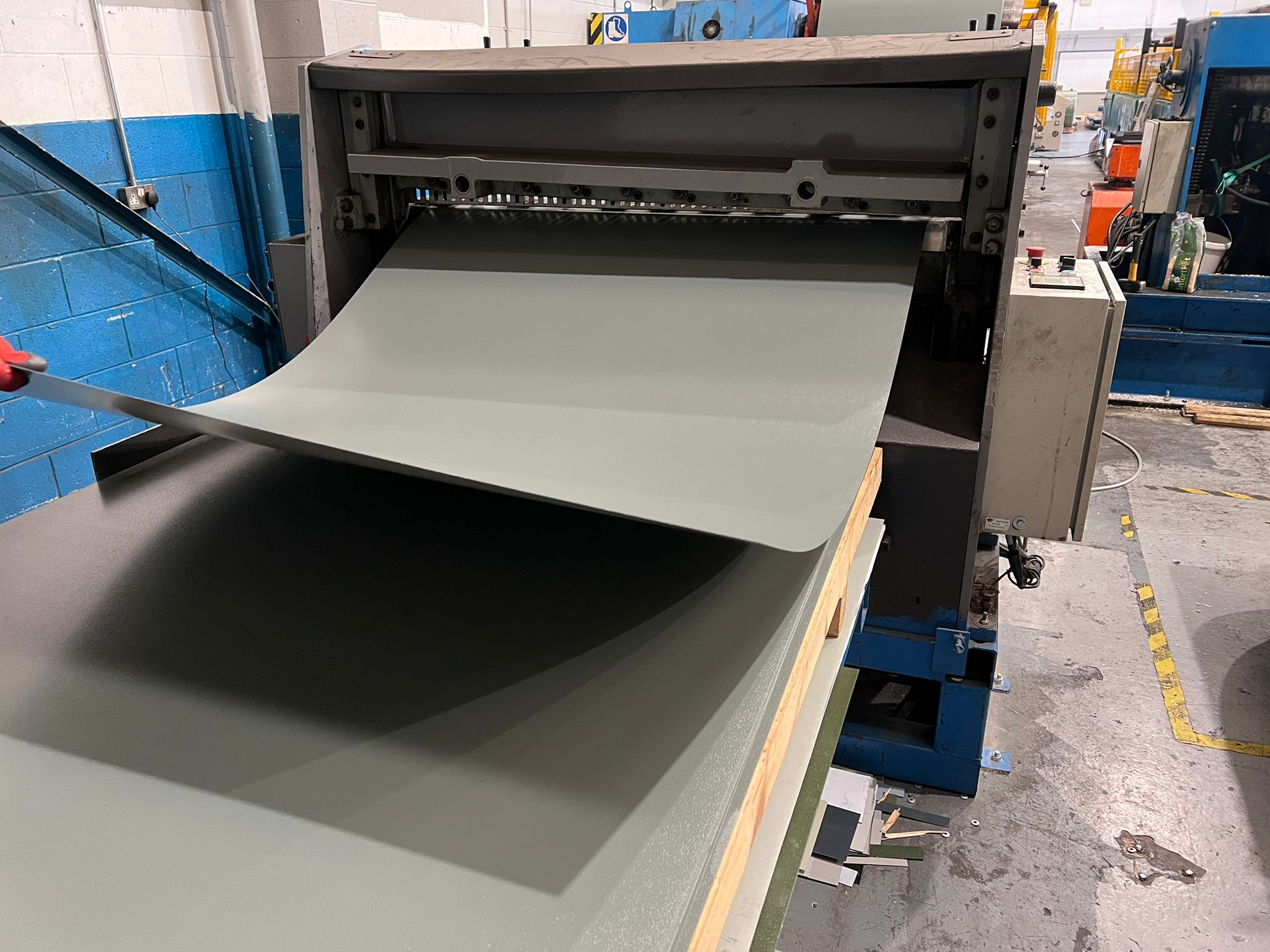

Metal Sheeting

Metal sheeting, such as aluminium or galvanised steel, offers durability, weather resistance, and energy efficiency. It can last 40-70 years and is resistant to rot, insects, and weather damage. Metal roofs also reflect heat, reducing energy costs. However, the initial cost can be higher, and installation requires expert knowledge.

Membrane Sheeting

Membrane sheeting, like TPO or EPDM, is lightweight, affordable, and relatively easy to install. Membrane roofs typically last 10-30 years but may need more frequent repairs. They are prone to punctures and damage from UV rays, requiring regular inspections.

How to Choose the Right Flat Roof Sheeting for Your Building

When choosing a flat roof sheeting material, several factors should be considered:

- Environmental impact: Look for recyclable materials like metal or PVC, which offer better sustainability.

- Climate suitability: Choose a material that performs well in your region’s climate, such as metal for hot climates or EPDM for colder areas.

- Insulation needs: Metal sheeting is more energy-efficient due to its reflective properties, whereas other materials may need additional insulation.

- Long-term costs: Consider the initial investment and future maintenance expenses.

Conclusion

When choosing flat roof sheeting, evaluating all factors such as upfront and long-term costs, climate compatibility, and material durability is essential. While more affordable materials may seem appealing, they might cost you more in the long run with repairs and replacements. Make an informed decision by discussing your options with a reputable roofing contractor, and you’ll enjoy a long-lasting, reliable roof.

FAQs About Flat Roof Sheeting

What are the common materials used for flat roof sheeting?

Common materials include asphalt roll roofing, modified bitumen, EPDM rubber, TPO, PVC, and metal roofing.

How do I choose the right flat roof sheeting material?

The choice depends on factors like budget, climate, roof slope, durability, installation method, and compatibility with the existing roof structure. Consulting with roofing professionals can help you make an informed decision.

Can I install flat roof sheeting myself?

While some materials are DIY-friendly, hiring professionals ensures proper installation and maximises the roof’s lifespan.